Product Description

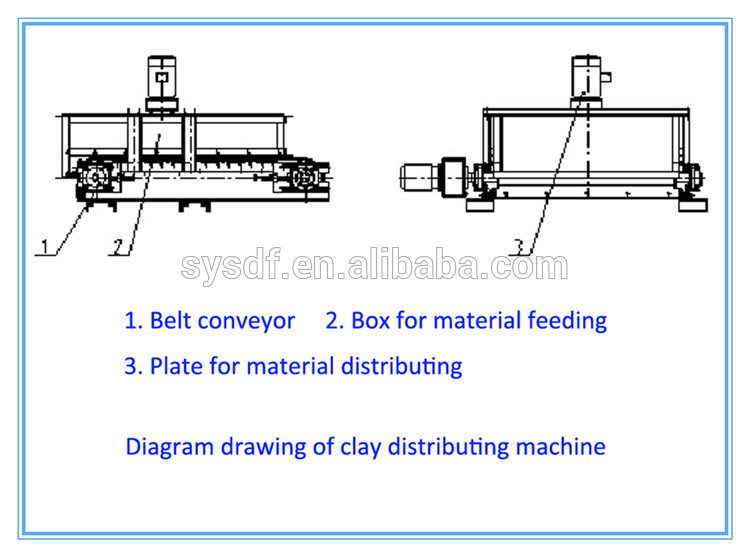

auto clay distributing machine

B80 raw material distributor is mainly used to make sure the crushed raw material evenly distributing along with the width of roller, make the material feeding for roller crusher uniform, the same wear, increase the treatment effect to the material, extend the service life.

Scope of application: applicable to coal gangue, shale,

Fly ash, clay etc with granularity of ≤50mm

Technical performance:

- Capacity ≥46m3/h

- Linear speed of belt: 0.3m/s

- Installed capacity: 1.5+1.5kw

- Weight: 895kg

Shuangyashan Oriental Wall Material Group was established in 1969 with the registered capacity of 30, 660,000 RMB, is one of subsidiaries controlled by China Energy Conservation New Material Investment Company. Its main business scope is supplying whole set machine of sintered brick making with the clay, shale, fly ash, waste coal, shale, etc as raw material. Now there are 7 factories totally in Beijing and Shuangyashan City which are 3 factories of brick making, 3 factories of brick machine producing, 1 Designing& Researching Institution and one kiln company, with the total capacity of 32,000,000$, 1045 employees including of 237 technical personnel.

Through repeated practice and innovation, we now developed the technology in brick making with coal gangue as raw material and the whole set of sintered hollow brick making with clay, shale as raw materia. The machine in brick making procession includes of raw material handling, extruding, cutting, bricks turning, bricks setting, transporting, drying, automatic controlling, firing in kiln, kiln cars running, etc.

Now our company have developed three typical aspects: the first, machine in series, means, the brick making machine we producing can meet the need of different producing capacity, different raw material and different price. Now we can supply the whole set of brick making machine with the capacity of 30,000,000 pcs, 60,000,000pcs, 80,000,000pcs and 120,000,000 pcs per year; The second, machine in whole set, means, we can supply the whole set of machine from raw material handling, moulding, cutting, brick turning and setting, kiln cars running; The third, machine automaticly controlled, means, the whole brick production line is controlled by computer, program controlled system and electricity automatic controll system.

HEADQUARTER IN BEIJING, CHINA

WORKSHOP OF SHUANGYASHAN ORIENTAL WALL MATERIAL GROUP

CONTROL SYSTEM FOR BRICK PRODUCTION LINE

Our Services

1. Turn-key project. From the raw material testing report, factory design, whole set of machine, kiln construction, to the service of installation and debugging.

2. SHUANGYASHAN ORIENTAL WALL MATERIAL GROUP CO., LTD can do the process layout design, dryer design and kiln design in accordance with the testing report and customers' requests.

We have the most authoritative technology and equipment research center in brick making industry.

3. AFTER-SALES SERVICE

The four brick factories both in Beijing and Heilongjiang Province adopt different raw materials, process and kiln t provide customers with industrial experiment, technical management, training and debugging.

FAQ

1. What is the raw material for making bricks?

For example, clay, coal gangue, shale, fly ash

2. Do you have testing report of raw material?

a. YES—it should include of physical and chemical performance. Please send us for reference

b. NO—please send us at least 15KG raw material to our lab for testing.

3. What is the brick size?

For example, 9”x4”x3”inch (Indian standard brick size)

4. What is the capacity of bricks per day (tons or pieces)

100,000 pieces

150,000 pieces

200,000 pieces

4. What is the fuel for burning bricks and its calorific value?

For example, coal, natural gas, diesel, heavy oil

5. What kind of kiln type you prefer to?

a. Tunnel kiln

(automatic control, low energy consumption, but high investment)

b. Hoffman kiln

(bad working conditions, high energy consumption, environment pollution, but low investment)

6. What is the automatic level?

a. bricks setting by manual

b. bricks setting by machine

7. How about the Land condition? Including of :

a. Square area

b. Satellite map with boundary

c. location and surrounding conditions

IF YOU WANT TO BUILD A BRICK FACTORY, FEEL FREE TO CONTACT US!!