Auto control system for kiln temperature

1. Introduction

The system is used to automatic monitor the temperature, pressure and humidity in the drying and burning process of brick production line, then depending on the monitoring result and the request of burning, control the switch of moisture-discharge fan, driving fan, hot air fan, cool fan and their air quantity (frequency control), control the switch of other fans (moisture-discharge fan, air pressure fan, mixing fan)

This monitoring system must cooperate with the kiln cars running system to guarantee the bricks drying and burning.

The core equipment of this system is industrial control computer (including configuration software), the operator can monitor the temperature, pressure, moisture of drying and burning through this industrial control computer at any time, can print and store the real-time report, also can operate the switch of fans, adjust the frequency (speed) of fan.

The system can automatically collect the data such as analysis temperature, pressure and moisture, automatically draw the curve of temperature, pressure and moisture and report, can realize automatic data storage, intelligent alarm, historical data query etc.

2. System components

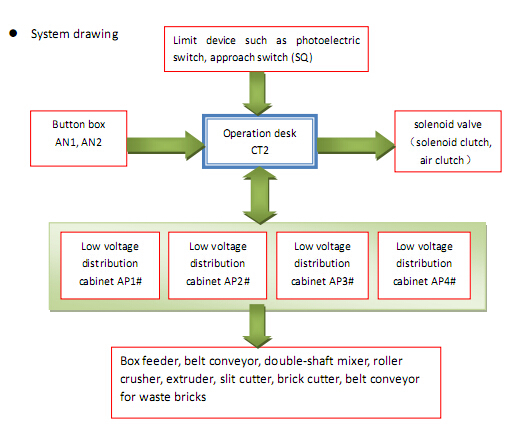

The system is mainly composed of operation desk for kiln temperature monitoring, Inspection instrument box, frequency conversion cabinet, fan cabinet (with PLC), monitoring device for temperature, pressure and moisture (with control cable, not include of power cable)

(1)Operation desk for kiln temperature monitoring(CT8)

It is the core equipment of this monitoring system, which connects all inspection instrument, frequency convertor, fan cabinet, PLC, including of industrial control computer ((including configuration software), HP color printer, UPS power, button (Schneider), indicator light (Schneider), RS485/232 converting module, 24b DC power, terminals. The power is from the fan cabinet.

(2) Inspection instrument box(AN1~2)

It is composed of inspection instrument, 24V DC power, breaker terminals, which is the core device to monitor the temperature, pressure and moisture, all the signal of monitoring device will lead to inspection instrument through special shield cable and the inspection instrument will deal them with the standard RS458 signal, then the signal will be transferred to industrial control computer through the RS shield cable.

(3) Frequency conversion cabinet(AP1~2)

It is composed of frequency converter, breaker, contactor, reactor, ammeter, voltmeter, current transformer, terminal etc, it can adjust the output current frequency to adjust the speed of the fan, can communicate with industrial control computer through RS shield cable, accept the control order of industrial control computer.

(4) Fan cabinet

It is composed of PLC, breaker, contactor, 24v DC power, indicator light, voltage

Meter and terminal, it can control the switch of fan in accordance with certain

program, communicate with industrial control computer through the RS shield

cable, accept the control order or industrial control computer.

(5) Monitoring device for temperature, pressure and moisture

It is composed of thermocouple(S, K), heat resistance, pressure transmitter, humidity transmitters. There are N pieces of temperature testing point for kiln, N points at the high temperature section, using S, other section using K. There are 3 points at the bottom of kiln, every one points for hot air fan and smoke-discharge fan. And there are N pieces of pressure testing points for kiln, N pieces of temperature testing for dryer, using thermocouple, N pieces of moisture testing points.